The use of metal-ceramic crowns in the prosthetic procedure makes it possible to restore the natural anatomical configuration of a damaged tooth, its functionality, and also its aesthetic appearance. The price of metal-ceramic crowns is quite affordable and therefore this prosthetic option is incredibly popular among most patients in dental clinics.

In the article we will talk in detail about the process of installing metal-ceramic crowns on a tooth: we will consider the types of structures, indications and contraindications for their use, and also find out how much a metal-ceramic crown costs at Vanstom Dentistry in Moscow.

Metal-ceramic crown: design features

An orthopedic prosthesis made of metal-ceramics is a special onlay that is worn during the prosthetic procedure on a tooth that has previously been subjected to the grinding process. The shape of the metal-ceramic crown is identical to the anatomical configuration of natural teeth and repeats it down to the grooves on the tooth surface.

If you look at the photo of the metal-ceramic crown that we posted below, you will see that the base for creating the structure is a solid metal frame and the thickness of its walls can reach 0.5 millimeters. The contours of the frame are similar to the contours of the “native” tooth. On top, the frame base is covered with a layer of ceramics, which matches the color of the natural enamel coating.

Fixation of metal-ceramic crowns is carried out by fixing them on the prepared tooth using a special cementing composition.

Manufacturing process

Patients who want to install truly high-quality metal-ceramic dentures should understand that this will not be possible quickly. It will take at least 10-14 days to produce them. The procedure for making crowns is as follows:

- The doctor applies a special mixture to the already ground teeth, which hardens almost instantly. After removing it, the dentist takes an impression;

- if the impression is made successfully, then it serves as the basis for creating a plaster model of the tooth being restored;

- Next, a model of a metal frame made of wax is developed. The finished model is transferred to a dental prosthetic workshop for the manufacture of a prosthesis from an alloy agreed with the patient;

- When the frame is completed, fitting is required. It is put on the patient’s teeth and if all is well, it is returned to the technicians;

- in the workshop, a ceramic composition is applied to the frame in two layers and sent to a specialized oven for heat treatment;

- then enamel is applied to the product, corresponding to the shade of the patient’s natural tooth covering;

- The orthopedist performs a control fitting. When the crown fits snugly and meets all the requirements, it is sent to the workshop again. There, a special glaze is applied to the prosthesis to add shine and the final firing is performed.

Only after all the above steps are the crowns considered ready for installation. If some specialists offer you shorter terms for making crowns, then this is a serious reason to doubt the quality of the products and the professionalism of the doctors themselves.

Materials for the manufacture of metal-ceramic crowns

Metal alloys

To produce the frame of a metal-ceramic crown in modern dentistry, three types of alloys from different metals are used:

1. Alloys of cobalt and chromium, nickel and chromium. The cost of a metal-ceramic crown made from these alloys will be as low as possible, but it is worth knowing that the listed metals often cause allergic reactions and irritation of gum tissue, and therefore the savings obtained when installing them are questionable.

2. Alloys of palladium, platinum and gold. This material for the production of prosthetics has a number of advantages: hypoallergenic, the ability to create the most natural tone of the prosthetic structure, which is especially important in the process of restoring teeth included in the smile line.

Another type of alloy that is used in the production of metal-ceramic crowns is a mixture with titanium as a base. Titanium alloys are not capable of causing allergic reactions; when used, the risks of rejection and incompatibility of the prosthesis with the tissues of the oral cavity are minimal.

Metal-ceramic crowns

from 8000 rub. More about prices

We have been working since 1994

we are one of the first to open private dentistry in Moscow

Best materials

only new and modern equipment for dental treatment

Free

consultation with a dentist

Payment options

- cash

- plastic cards

- cashless payments

Doctors' experience

- with great experience

- graduated

- conference participants

Types of alloys in metal ceramics

Gold-platinum alloy

The classic version with which orthopedic dentistry began. The first crowns were made from gold at the end of the 19th century.

Nowadays, many materials have appeared that, along with solving the problem of restoring chewing function, are quite durable and at the same time meet high aesthetic and cosmetic requirements. But gold, as a material for the manufacture of frames for metal-ceramic prostheses, is still relevant today.

Only a noble alloy can adhere so precisely to the treated tooth, which practically eliminates disintegration and recurrent caries. Gold almost never causes allergies.

The disadvantage of using a gold alloy is the limitation on the length of the intermediate (located between two supports) part of the metal-ceramic bridge (in the manufacture of metal-ceramic bridges), as well as the price: the cost of such a crown is from 10,000 rubles.

Sometimes, to improve color rendition, on a metal frame cast from other metals. a thin layer of gold is applied, which illuminates through a layer of ceramic mass with a warm yellowish color.

Nickel alloy

Most often, nickel-based alloys are used to cast the frame, which is the most accessible of the metals that can be the basis for metal-ceramics. With nickel alloys there are no problems when casting and fitting in the patient's mouth.

However, despite all the advantages, nickel has a serious drawback. This metal is a strong allergen.

Our body's daily need for nickel is thousandths of a gram, and the production of one metal-ceramic crown requires 2 grams of an alloy containing 1.3 grams of nickel. Thus, the metal is in contact around the clock with the oral mucosa, tooth tissues, and jaw. The result is allergic reactions and weakened immunity.

In Germany, they abandoned the use of nickel in dental prosthetics 10 years ago (as well as stainless steel back in the 30s).

Cobalt-chromium alloys

The most optimal option taking into account biocompatibility and cost.

In cost, they are only 1.6 times more expensive than allergenic nickel alloys. The biocompatibility of the cobalt alloy is 36% (for the gold-platinum alloy it is 42%, and only one’s own teeth are 100% biocompatible), they are non-toxic and do not cause allergic reactions. Cobalt alloys are durable, and metal-ceramic bridges of fairly long length can be made from them.

Chromium alloys are not dangerous; only some of its salts are poisonous, but they cannot form in the oral cavity.

Molybdenum

A non-toxic metal, it is added to dental alloys in very small quantities to improve casting properties.

Beryllium

This metal is a carcinogen. It causes granuloma (a type of malignant tumor) in the lungs, liver, spleen and heart. Upon contact with beryllium, skin diseases develop and a severe weakening of the immune system is observed. In Russia, its use in dental alloys is prohibited.

Metal-ceramic crowns before and after photos of our patients

Photo before

Photo after

Ceramic coating

The metal frame of the orthopedic structure is covered with a layer of dental ceramics, which in composition is almost similar to household ceramics, however, the compositions for lining metal-ceramic crowns contain an increased content of components such as albite and orthoclase, which increase the strength of the created layer.

The ceramics are applied to the frame in layers and specialists use a special tool for this work. After applying the next layer, the structure is fired in a vacuum oven. This is necessary to ensure the strongest possible adhesion of the ceramic layer to the frame.

Reviews of metal-ceramic crowns from patients indicate that this type of dental orthopedic structures is not only strong and durable, but also highly aesthetic, which makes it possible to regain an attractive and natural smile!

How long does cermet last?

Dental crowns made from metal ceramics are quite durable. On average, the service life of products is at least 10-12 years. But patients who choose this type of prosthetics need to know that the service life directly depends on several factors:

- correct preparation of teeth for prosthetics. If the canals are filled with poor quality, inflammatory processes soon occur, the gums become swollen, and the patient feels severe pain. As a result, the dentures have to be removed, the tooth must be treated, and the denture must be made in a new way;

- orthopedic professionalism. It is very important that the doctor performs the grinding of hard tissues flawlessly. If irregularities and tubercles remain on the tooth, then the prosthesis will not fit tightly to the tooth tissue. Food, saliva and air enter the resulting gaps and very soon carious processes occur in such cases;

- experience and technical skill. It determines how closely the prosthesis matches the shape and shade of natural teeth.

By seeking prosthetic services at the Beryozka clinic in Balashikha, you can be sure that all stages will be performed flawlessly and you will receive a guarantee on the installed crowns.

Indications and contraindications for the installation of metal-ceramic crowns

Installation of a metal-ceramic crown is indicated in the following circumstances:

1. If there is a need to reconstruct damaged teeth to restore full chewing function and aesthetic appearance.

2. Metal-ceramic crowns are indicated for installation in case of abnormal position of teeth in a row, to eliminate a number of aesthetic defects: discoloration of natural enamel, severe chips.

Like any other medical procedure, prosthetics with metal-ceramic structures also has a number of limitations:

1. Metal-ceramic crowns cannot be installed if you are allergic to metal alloys.

2. You should refrain from the procedure if you have weak and painful gums, periodontal diseases, or malocclusion.

Metal-ceramic crowns are not placed on young patients under 16 years of age.

How to install a crown

Installation of crowns on metal-ceramic teeth begins with a general examination: the doctor prescribes preparatory treatment procedures, if any are needed.

Preparing your teeth

– this is a careful gentle grinding, in difficult cases – removal of the nerve. If the condition of the molars does not require pulp preparation, then they are left “alive”.

Impressions are taken, from which crowns will be made that completely replicate the shape of the natural tooth. An enamel color close to natural is selected.

The installation process takes from a week to two, taking into account the individual characteristics of the patient, the need for additional preparatory procedures for sanitation, professional cleaning and other nuances.

The process of installing metal-ceramic crowns

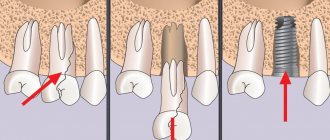

The main task of a specialist in prosthetics using metal-ceramic crowns is the accurate reconstruction of the root part of the tooth and its crown part. This is essential for completely restoring the functionality of the tooth.

In the restoration of the root part of the tooth, the following can be used:

- Stump inlays. Their use is advisable when the tooth root is healthy and does not have significant damage;

- Dental implant in cases of lost root part.

The prosthetics process takes place in two main stages, which are worth talking about in more detail.

Stages of dental prosthetics

The quality of prosthetics largely depends on the correctness of the preparatory stage. Therapeutic tooth preparation includes:

- X-ray diagnostics, which allows you to identify hidden inflammatory processes and evaluate the quality of root canal filling - if a specialist detects violations, treatment is carried out before prosthetics;

- depulping the tooth eliminates the risk of inflammation due to thermal burns of the pulp;

- treatment of caries, removal of old low-quality fillings;

- making a core inlay for crowns if the coronal part is severely damaged, and in case of minor destruction, specialists use pins and filling material.

The specialist begins the immediate stage of prosthetics only after high-quality therapeutic preparation. The doctor grinds the tooth down to the thickness of the future prosthesis and makes an impression, which will be used to make a metal-ceramic crown in a dental laboratory. This will take some time, and during the prosthesis manufacturing stage the patient will wear temporary plastic dentures, which will hide from prying eyes and protect the ground teeth from the negative influence of the environment.

Free consultation on the cost of treatment in our dentistry

Leave a request and the clinic administrator will contact you within 15 minutes!

Preparatory stage:

1. The patient comes for examination to a specialist. After assessing the condition of the tooth and a series of studies, the dentist makes a decision on the prosthetic technique.

2. If the root part of the tooth is alive, then it is possible to carry out a series of therapeutic manipulations, during which the specialist eliminates all inflammatory and destructive processes, if necessary, the dental canals are re-filled and a pin is applied.

If the tooth root is significantly weakened, then the pin cannot be used, and in this case, before installing a metal-ceramic crown, the specialist uses a stump spacer, designed to replace bone tissue that has undergone the process of destruction.

3. If the root of a tooth is missing or severely damaged, a dental implant must be installed. A metal-ceramic crown on an implant will cost more than other options, but this type of prosthesis has maximum durability and strength and is visually indistinguishable from natural teeth.

After all clinical training activities are completed, the second stage of prosthetics begins - laboratory.

Laboratory stage of installation of metal-ceramic crowns:

During the laboratory stage of prosthetics with metal-ceramic crowns, the structure itself is manufactured. The process consists of the following stages:

- Taking impressions of the patient’s teeth;

- Modeling of the structure frame;

- Trying on the finished prosthesis;

- Correction of possible defects.

The process ends with the installation and fixation of a metal-ceramic crown.

Fixed dentures

Fixed restorations include inlays, veneers, crowns and bridges. The manufacturing scheme differs only in small details. For example, let's take the manufacture of a bridge structure.

Preparation for the manufacture of a fixed denture begins with collecting anamnesis, making a diagnosis and preparing the teeth. The first clinical stage ends with the taking of impressions.

First laboratory stage

The impression technician makes a plaster cast and wax base with occlusal ridges. The model is then handed over to the doctor to determine the central occlusion. After this, the model goes back to the technician.

Second laboratory stage

The technician places the model in an articulator (a dental apparatus that simulates the closure of the jaws) and prepares models of ground teeth. Models crowns on abutment teeth and artificial teeth between them. Depending on how the denture is made, the technician makes metal crowns by casting, ceramic ones by pressing, and grinds zirconium crowns on a milling machine. The bridge is transferred to the orthopedist.

The dentist tries on the crowns and adjusts them. Notes any imperfections and sends them to the technician for final processing.

Third laboratory stage

The structure is polished and ground. In the case of metal ceramics, the metal base is processed and a ceramic coating is applied to it. The finished bridge is sent to the orthopedist, who fixes it on the patient’s teeth.

The production of dentures for the upper jaw follows the same protocol as for the lower jaw.

Prices for prosthetics with metal-ceramic crowns in Moscow

Moscow dentists offer different prices for metal-ceramic crowns. Prices for the service depend both on the clinic’s pricing policy and on a number of completely objective factors, including:

- Material for the manufacture of metal-ceramic crowns;

- The complexity of the clinical stage of preparation for prosthetics. Metal-ceramic crowns on an implant will be the most expensive option, since the process of installing them is a specific and complex task.

Do you want to restore lost teeth by installing metal-ceramic crowns? Contact our Vanstom dental clinic in Moscow: we guarantee high quality work in which we use modern materials and technologies, and will also pleasantly surprise you with affordable prices for metal-ceramic prosthetics.

Technological aspects of metal ceramics

In the process of manufacturing metal-ceramic structures, there are a number of key points that deserve special attention.

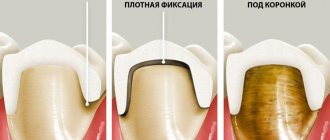

- Tooth preparation for metal ceramics.

- The tooth must be prepared (ground) with a ledge at the gum level.

- The total thickness of the metal frame and the ceramic mass covering it is about 1.5 mm. As a result, if the tooth is ground without a ledge, we get the edge of the crown hanging over the gum and pressing on it. The crown presses against the blood vessels and a “bruise” forms. The metal frame comes into direct contact with the gum, and metal ions cause it to darken.

- In the case of preparation with a shoulder, the edge of the metal-ceramic crown rests on the hard tissues of the tooth without injuring the mucous membrane. This technology is quite labor-intensive, and its implementation requires a modern dental unit and, of course, the qualifications of a doctor and dental technician.

- The intermediate part of the metal-ceramic bridge prosthesis should also not put pressure on the mucous membrane (gum), otherwise bedsores may form. Of course, in those places where it is visible, you have to make a compromise, but in any case the touch should be very gentle. And if food gets into a place where there is a loose seal, it will be much easier to remove it from there than in the case of the “full contact” option.

- Many doctors “sin” by depulping (removing the nerve of the tooth) even healthy teeth under metal-ceramics, which is not always justified, since modern technologies make it possible in many cases to avoid this procedure. Depulped (dead) teeth cannot resist infection and often have to be re-treated. In addition, a pulpless tooth becomes more fragile and can collapse under a heavy metal-ceramic structure.

Metal-ceramic crowns: price

| — Consultation with a dentist-orthopedist | 0 rub. |

| — Metal-ceramic crown | 8000 rub. |

| — Metal-ceramic crown with a ledge | 10,000 rub. |

| — Metal-ceramic crown on an implant | 12000 rub. |

| — Metal-ceramic crown on precious metals | from 14500 rub. |

| — Metal-ceramic crown with effect masses | 13000 rub. |

| — Metal-ceramic crown with cervical mass | 13700 rub. |

View price list

Caring for metal-ceramic crowns

Along with the fact that caring for artificial metal-ceramic teeth is quite simple, there are some rules that, if followed, can extend the service life of the products:

- You need to brush your teeth at least twice a day. Movements should be vertical, directed towards the tooth edge from the gum;

- The brush should have soft bristles. Any paste can be used according to the patient’s individual preferences;

- You should not limit yourself to just brushing, since food remains remain in the interdental spaces. To remove them, you need to use dental floss;

- After brushing, you should rinse your mouth with clean water and only then use an antiseptic mouthwash;

- Lovers of coffee or other coloring foods and drinks, as well as smokers, are recommended to have their teeth professionally cleaned at least twice a year. Whitening pastes will not provide a positive effect in caring for metal ceramics, so home whitening is not advisable.

In addition to hygiene procedures, you also need to know that strong mechanical loads can lead to cracks and chips in the ceramic coating. Also, sudden temperature changes worsen the condition of the dentures, so it is not recommended to eat excessively hot or very cold food.