3D printing has become widespread in many fields, and medicine is no exception. The technology helps create prosthetics for various purposes, simplifying, reducing the cost and improving the quality of the final product. The greatest demand for developments is observed in dentistry. Let's consider the main aspects of using three-dimensional modeling and printing, why you need a 3D printer for dentistry, what materials are used and other nuances of the innovative method of dental restoration.

Modeling and printing: what you need to know?

Modern 3D technologies are accompanied by a rigid sequence that includes:

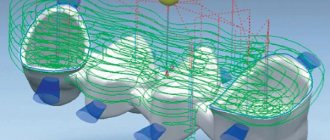

1. Obtaining a three-dimensional model. Printing is done on the basis of a digital file that shows the proportions, color palette, and relief of the future workpiece. To create it, special scanners are used that take measurements and convert the resulting data into digital format.

2. Improvement via software. Professional 3D scanners are not perfect enough; deviations may appear during data acquisition, which are eliminated in special-purpose programs. In a number of industries, including medicine, software corrects defects independently thanks to an intelligent system.

3. Print. A special 3D printer for dentistry produces a prosthesis or other workpiece, which is subsequently used for treatment.

Let's consider some technical aspects of each stage, including the choice of material.

3D visualization solves the following problems:

- identifies objective aesthetic problems at the time of patient’s treatment;

- performs virtual modeling of the future shape and position of teeth;

- allows you to justify the treatment plan, for example, before installing a partial denture on the upper jaw, and the advisability of involving orthodontists or implant surgeons.

For design, standard tooth shapes from a data bank or the patient’s own teeth are used. Design tools - moving teeth, rotating, deforming and scaling individual parts.

Obtaining a 3D model

To obtain three-dimensional models, professional and expensive equipment is used, which is highly accurate and easy to operate. It is important to note that practitioners use 2 methods of obtaining a workpiece for 3D printing:

1. Scanning a plaster cast. The doctor makes an impression, after which the latter is processed with a special device. The inconvenience lies in the increased time spent and increased requirements for revision.

2. Intraoral scanning. Devices like 3Shape Trios 4 or Shining DS-EX Pro take data directly from the patient’s jaw. This is faster, but the cost of such devices is higher.

3D printers and scanners in dentistry have improved every year, and their costs have decreased significantly. Therefore, today even small clinics have similar technologies.

Printing cost calculation

Any new technology is doubly good if it also brings additional economic efficiency for users. Knowing the weight of the material required to create a particular model, you can calculate the cost of printing. For example, to create one demo model, you will need about 25 grams. resin, surgical template and aligner model - about 15 g.

Therefore, the cost of printing one model will be as follows:

- 25 gr. resin (for demo model) Dental Peach will cost you 190 rubles, 15 g. (models for aligners) – 115 rub.

- 15 gr. Dental Yellow Clear for templates will cost 150 rubles.

Based on this simple calculation, you can make a comparison with the methods of creating models that you use now, and understand how quickly you can return your investment in purchasing the equipment you need.

Finalization of the 3D model

Today, there are several options for printing dental prostheses, which differ in the type of material used, the method of forming the blank, and so on. Regardless of the option, increased demands are placed on the quality of the model. To do this, the layout is modified using special software. This can be general or specialized software. Rework is required to eliminate serious defects, improve quality and reduce the time required for post-processing immediately after installation of the prosthetic tooth. To improve quality, modern printers have support and special add-ons.

Printing a prosthesis with a 3D printer

As noted earlier, modern dentistry uses several technologies. The most successful solution is printing with SLA/DLP/LCD photopolymers. Printers of this type are characterized by a high level of accuracy and productivity. The technological process involves making a workpiece and then hardening it under a certain light source (SLA - laser, DLP - projector, LCD - light matrix).

Each of the presented technologies has advantages and disadvantages. Previously, price was considered a serious drawback, but over the past 20 years it has been possible to reduce the cost of equipment and materials tenfold. When choosing devices, it is important to consider several factors, including printing speed, the platform for constructing the prosthesis, and the use of various properties. Among other things, it is recommended to evaluate the ease of working with a slicer, which is responsible for transferring a three-dimensional model into a workpiece. Each manufacturer offers its own developments, which can be evaluated online.

Top sellers in the domestic market

Choosing a 3D dental printer is a very difficult task, because there is a significant variety of technical tools and solutions on the market. The purchased product must meet a number of characteristics: printing speed, convenience, quality of the result. Among other things, products must have an acceptable price for purchase and further maintenance. To simplify the task, we recommend paying attention to market leaders who have proven themselves on the positive side:

1. Elegoo Mars 2 Pro 3D printer (Mono LCD). Considered the best budget option of 2021 according to Amazon. A simple, convenient and versatile option for small dental clinics. Key advantages include increased speed, low maintenance costs, high precision, and reliable support elements. Another advantage is Russification, which simplifies working with the interface. Its analogue in terms of technical characteristics is Phrozen Sonic Mini.

2. Elegoo Saturn Mono 4K 3D printer. The best option in the line of 3D printers for dentistry from Elegoo. The device falls into the middle price segment and is designed for jewelry making and working with dentures. It is based on the use of modern LCD printing. Unlike Mars 2 Pro, there is an improved platform for forming blanks, work with 4K resolution, improved detail down to 50 microns and increased speed. The set includes a convenient all-metal bathtub. Another significant advantage is the ability to connect the equipment to the Internet with a cable.

3. Anycubic Photon Mono X. If you need professional equipment with a high price segment, then you need to consider Anycubic products. The product has an increased working area and is equipped with a monochrome LCD 4K screen. The latter guarantees an increased level of accuracy and unique printing speed. Photon Mono X works with any photopolymer resin, providing versatility. The connection to the Internet is via Wi-Fi, and the software is compatible with both Windows, Mac, and Linux.

In the premium segment, we can highlight the products of Formlabs. But due to the significant purchase and maintenance costs, it is difficult to find on the domestic market. The above mentioned models are available to order right now through our website.

3D in dentistry: what technologies are used?

The following 3D printing technologies are most often used in dentistry today:

- SLM. This is a laser melting technology for working with metal. It can be used to create braces and implants. A build plate is placed on the heated working platform of the printer, and metal powder is applied to the plate layer by layer. The laser beam scans sections of the layers. Once one layer is ready, the platform is lowered down to the thickness of one layer. This will be repeated until the last layer is printed.

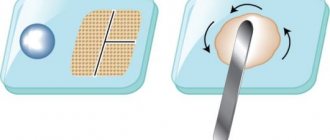

- SLA. Laser stereolithography is used in areas where maximum precision of parts is important. The mesh platform is placed inside a container filled with liquid polymer. Under the influence of a laser, the polymer hardens in certain areas. The platform sinks down layer by layer. The finished print is placed in a bath with a special solution to remove unnecessary elements from it.

- LCD. The printer is equipped with a liquid crystal matrix through which light from LEDs passes. This matrix is similar to the one installed in smartphones we are used to. In this case, the luminous flux is dimmed by the display. Under the influence of a laser, the liquid photopolymer in the bath hardens layer by layer. Unlike SLA technology, the entire layer is illuminated instantly, and not at individual points, which significantly speeds up the printing process.

- LFS. Low power stereolithography is similar to SLA, but makes the printing process less complex and more economical. Formlabs has developed a unique light processing unit for this technology to achieve a flawless print surface. LFS printers can usually resume the printing process after a pause or unexpected stop without affecting the quality of the print.

ATTENTION. Trends in technology development are such that 3D printing is becoming less and less expensive and faster. Operating a printing device is becoming increasingly easier, and the accuracy and detail of finished prints is steadily increasing.

Here are examples of 3D printed dental products:

Material and manufacturers

Dental 3D printers often have limitations in the type of materials used. Therefore, the purchase of consumables should be carried out in accordance with the manufacturer’s technical recommendations. As for the available offers on the market, here we need to highlight:

1. NextDent (Holland). The company's products are fully biocompatible, which means they are safe for use in medicine. The resin has been certified and meets CE and FDA standards. Gingiva Mask, used to imitate human mucosa, is especially popular among dentists.

2. Detax (Germany). The German company offers several lines of resins that are intended for dentists. This should include the Ortho and Splint range.

3. HARZ Labs (Russia). A young company that has proven itself on the positive side. Resins are distinguished by safety and versatility, which is necessary for specialists of a narrow profile. The company's products have the best price-quality ratio.

4. Formlabs (USA). Consumables from this manufacturer are used only in premium equipment of the same brand. This causes an increased price, which is unrealistic for most clinics and dental offices.

We offer almost all popular consumables used in medicine. You can select and order them through the main catalog.

What can be produced with a printer?

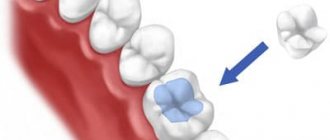

The use of a modern 3D printer in dentistry in combination with high-quality materials makes it possible to create:

1. Surgical templates. Universal aligners used to install implants in the right place and at the right angle. They are performed automatically using narrow-profile equipment. HARZ Labs Dental Yellow Clear resin is excellent for these purposes, which is distinguished by its odorlessness, high strength, and thermal resistance.

2. Temporary bridges and crowns. For the treatment of diseases, phasing with time is often important. This is why temporary crowns and bridges are used to improve the client's comfort and convenience. It is better to make them with Dental Sand A1-A2 photopolymer, which is available in various color options. Accompanied by biological safety and sufficient hardness.

3. Creation of a demo and master model of ceramic crowns and aligners. Polymer Dental Peach and HARZ Labs Dental Cast are suitable for these purposes. Consumables are distinguished by a high level of safety and improved physical properties. When making a crown, casting is performed in special molds.

4. Gum models. For this purpose, resins are used, which differ in their resistance to deformation. These are usually durable, glossy options, such as HARZ Labs Dental Pink. The products are also safe, color consistent and durable.

In some cases, options with increased requirements for rigidity, heat resistance or strength are applicable. For this purpose, special, reinforced polymers are used.

Cost of manufacturing models

In any professional activity, it is important not only to perform quality work, but also to calculate its cost. When working with a 3D printer, the procedure for setting costs and prices is greatly simplified. To create a demo model you will need about 25 grams of resin, for templates about 15 grams, as well as for aligners. Depending on the line of photopolymers and its actual price, the cost is calculated. As for the final price, everyone has the right to set their own premium.

Opportunities of digital dentistry

- Implantation.

Digital dentistry has been very actively integrated into the implant treatment of patients. First of all, this involves treatment planning and the production of surgical templates. The doctor uses special programs to determine the places where the implants will be installed. Then a surgical template is made on a milling machine or 3D printer, the surgeon moves it into the patient’s oral cavity and installs implants through special shafts. Such surgical navigation eliminates the occurrence of errors as a result of dental implantation and the risk of damage to some structures, canal, and maxillary sinuses. Using this technology, even before installing the implant, you can make a temporary or permanent crown. The surgical template is especially important when the patient’s situation with bone grafting is not very good - you need to calculate the location for installing the implant as accurately as possible. It is dangerous to do this by eye.In the digital dentistry clinic, you can make a surgical template on the day the patient arrives, as well as install implants and perform prosthetics with temporary or permanent structures.

- Orthopedics.

With the help of digital technologies, inlays, crowns, veneers are made very quickly and with high quality, and prosthetics on implants are performed. Already today, doctors have the opportunity to make complete removable dentures using computer milling or prototyping. - Therapy.

No matter how good the composite material is, it has its drawbacks: after 2-3 years of service, shrinkage begins, the filling material absorbs moisture and loses its strength and aesthetic properties. Using digital technologies, it is possible to produce a ceramic inlay, which in its characteristics cannot be compared with a composite filling. - Orthodontics.

In this area, 3D digital dentistry in Moscow is also widely used, starting from planning orthodontic treatment, when the computer itself predicts the movement of teeth. Today, many companies offer bite correction using aligners, but before this, computer treatment planning takes place, and even before it begins, the patient sees the final result, knows how many sets of trays will be needed and how long the correction will last.

Before and after prosthetics on implants. Work by Apresyan S.V.

Post-processing and perfection of the prosthesis or model

Any “raw” workpiece requires post-processing, which guarantees an ideal surface and the desired physical properties. For these purposes, 2 additional devices are provided, which are often not included. The illumination chamber and ultrasonic cleaner stand out here. Typically post-processing includes the following steps:

1. Treatment with industrial alcohol. This allows any remaining resin to be removed.

2. An ultrasonic bath is used for additional processing. The cleaner does the job perfectly.

3. UV chamber is the last stage of exposure to the workpiece. It is used to increase strength, which is the most important performance property. The process takes no more than 15 minutes.

Today, the market offers special kits that speed up the process without sacrificing quality.

Main advantages of CT

- Speed of research. The study itself takes 15-20 seconds. Its results are immediately reproduced on a computer. The radiologist spends several minutes transcribing the data, burning a CD, and printing the images. The patient does not need to wait for the doctor to “develop” the images.

- Convenient storage and transfer of data. Film photographs fade and lose clarity over time. Images on a CD can be stored indefinitely. Over the Internet, data from the disk can be sent to the attending physician or other specialists for third-party consultation.

- Safety. The radiation dose of CT is lower than that of traditional panoramic examination (orthopantomography).

- High reliability and accuracy. 3D computer photographs of teeth are clear and detailed. This makes it possible to get an accurate picture of the location, size and shape of all structures of the patient’s dental system. The doctor does not have to do repeated studies to clarify the diagnosis.