Not every person has a complete set of teeth; with age, almost everyone has to deal with the issue of restoring lost units. The choice of method depends on several factors, one of which is price. During a consultation with a dentist, the patient receives all the necessary information about how much a dental prosthesis of one type or another costs, how prices for various services are determined, and what can or cannot be saved. Let's look at some of these questions.

What is it like?

Metal dental crowns are made from dental sockets.

They are produced by factories and enterprises specializing in medical equipment. The sleeve looks like a cap with thin walls. Most often, thin stainless steel or titanium alloy is used for manufacturing. Noble metals can also be used, but are less common.

When making sleeves, template dimensions are always used. They differ depending on the material. The thickness of the sleeve made of sheet metal is 0.2 - 0.22 mm, of gold 0.25 - 0.28 mm. The metal sheet itself has a size of 2.3 to 3.0, regardless of the material. The diameters of the sleeves are standard: from 7 to 12 mm with a difference of 1 mm. The height ranges from 10 to 12 mm.

Available in packs of 100 pieces.

General overview

Metal dental crowns are made from dental sockets - products in the form of a cap with a thin wall. They are produced by dental laboratories and specialized factories that produce medical equipment.

The most famous domestic enterprises producing dental sockets are Vega, Polymer Dentistry.

The material for dental sockets is thin sheet stainless steel, cobalt chromium or titanium alloy. Much less common are noble metals (gold, palladium, silver).

The thickness of the sheet steel used is 0.2-0.22 mm, gold plates - 0.25-0.28 mm. The dimensions of the platinum and gold plates from which the cartridges are drawn vary from 2.3 to 3.0 cm.

The diameters of the sleeves are standardized and have the following dimensions: from 7 to 12 mm (with 1 mm intervals), from 12 to 15.5 mm (with 0.5 mm intervals), 16 and 17 mm. The height ranges from 10 to 12 mm.

Sleeves of certain diameters and sizes are sold in sets of 100 pieces. The price of one set of steel products is 200-400 rubles.

Manufacturing Basics

The production (broaching) of sleeves is carried out on special machines, which can be different in design. The mold of one of the traditional models consists of two disks, one of which contains punches (cylindrical rods) with a diameter of 3 to 24 mm. The other is the holes into which the punches fit.

The diameters of the punches and holes working in a pair differ by 2 thicknesses of the sheet blank from which the sleeves are made. The punch size is smaller than the hole size. During operation in the closed state, the cap placed on the punch enters the center of the die.

Standard broaching machines operate by manual action on a screw and lever. Today, equipment with pneumatic drive has been developed and used.

In order not to subject the sheet blank to too much plastic deformation, which could cause it to crack, broaching is performed in stages. The sleeve is pulled sequentially in several dies with a gradual decrease in diameter.

At the first stage, the workpiece in the form of a round plate is placed on the matrix so that its center exactly coincides with the center of the matrix. This is very important, since even a slight displacement can lead to marriage.

When the punch moves down and presses it onto the workpiece, the latter is transformed into a cap, the outer diameter of which fits into the hole of the matrix, and the inner diameter covers the punch.

The product obtained after the first stage looks more like a cup than a cap. Subsequently, when pulling it through holes with a smaller size, the diameter of the sleeve gradually approaches the required one.

Reducing the number of broaching stages (skipping some of them) is unacceptable. This may cause the sleeve to rupture and damage the punch.

At the first stage of stretching, it is important to prevent the formation of folds on the walls of the product. To do this, it is recommended to put 2-3 layers of paper on a flat round piece.

During plastic deformation, the liner material hardens, becomes harder and stronger. This phenomenon, called cold hardening, is characteristic of any metal subjected to plastic deformation.

This is interesting: Splinting of loose teeth - what is it or how to save loose teeth

Pulling the hardened material may cause the sleeve to rupture and the punch to break. Therefore, after each broaching, the workpieces are softened by tempering. For steel, this operation involves heating the product in a furnace to 1100-1200°C and cooling it in air or water.

Removing the hardening of sleeves made of noble metals is done by heating them red-hot on an alcohol or gas burner. As a result of tempering, the liner material becomes plastic again and can be subjected to further broaching.

The advantages of stamped metal crowns include sophisticated technology, high strength, predictable results, and low cost. There are no problems with removing the prostheses; if necessary, they are simply cut.

Selection rules and nuances

The dental sleeve for making a crown from it is selected taking into account the individual characteristics of the structure of the tooth for which it is intended.

In order for prosthetics to be performed correctly and not cause discomfort, the crown must extend 0.3 mm into the space between the gum and tooth.

If there is a gap between the gum and the crown, then plaque will form on the tooth; if the crown sits deeper, the gums may become inflamed and a feeling of pain will appear. The sleeve should be flattened to fit the oval shape of the tooth.

Gold of 850 to 900 standard is most suitable for making a crown. Pure metal, as a rule, is not used; alloys of gold with copper or silver are preferable, because they are much stronger.

Gold from 850 to 900 samples is most suitable for making crowns

Gold crowns, unlike steel ones, are made not only by stamping, but also using casting technology. While gold dentures in the mouth are still considered “kisch”, bad taste, but in the era of the development of modern technologies in dentistry, this is no longer the case. Due to its chemical properties, this noble metal is excellent for placement in the oral cavity:

- Does not cause the growth of pathogenic microflora

- Highly hypoallergenic and biocompatible with the body

- Due to the softness of the metal, antagonist teeth are not injured

- Complete inertness to food and bodily fluids entering the mouth

- Combined with softness it is durable

The service life of gold crowns is much longer than that of steel or made from other metals.

Not every clinic provides the service for installing gold crowns. To do this, the doctor is required to obtain a license to work with precious metals, and this is quite difficult to do.

Stamping of crowns

There are 3 ways to stamp crowns from dental sockets:

- Parker (external treatment);

- MMSI;

- Sharpe (internal processing).

Consider Parker's method. Once a suitable dental socket has been selected, it is tempered and free-forged to a shape that approximates the configuration of the crown.

This is done on a dental anvil with metal (steel, copper, brass) or non-metallic (plastic or horn) hammers. The former are used for processing products made of steel, chromium-cobalt and titanium alloys, the latter - for models made of soft noble metal.

Free forging of crowns consists of rounding the transition from the bottom of the socket to the wall, and giving it a shape close to the covered unit of the jaw row. To do this, the bottom of the sleeve is rounded on the anvil process.

Then another process is installed, having a shape close to the tooth. The bottom of the product is upholstered on it, minting the shape that the tooth has. In this case, the blows are directed from the center of the bottom to the walls.

After this, the sleeve is tempered and the crown is given a shape that fully matches the shape of the dental element.

For this purpose , stamps are used that have a relief on the end that corresponds to all functioning surfaces of various teeth. A stamp is used to make an imprint on a lead plate corresponding to the shape of the tooth being coated (cutting edge of the incisor or fissures and cusps of premolars and molars).

Then, a stamp is inserted into the sleeve placed with the bottom on the lead plate with the imprint, and it is hit with a hammer so that the bottom of the cap takes on the relief of the tooth. After this, the chewing or cutting edge of the crown surface is processed up to the equator of the stamp.

The video shows the process of making a stamped crown.

This is interesting: Installing a ceramic inlay to restore tooth integrity

Rules for stamping crowns

Stamping rules:

1. Following directions. To avoid unnecessary folds on the crown, forging should begin from the chewing surface to the equator.

2. Impacts on the cutting surface are excluded, as they can deform the product.

3. Do not hit the neck of the cap, as this can damage it, making it difficult to remove.

4. You can stretch the crown on the stamp if it does not fit on the axle.

There is no need to allow the crown walls to become depleted. It’s better not to knock with a hammer again. In this regard, external stamping is more acceptable than internal stamping.

During manufacturing, the product is subjected to heat treatment. And precious metals are boiled in a solution with hydrochloric acid, which makes its surface more vulnerable to deformation. Therefore, it is better to use a horn hammer.

A metal crown is the most common orthopedic device. A dental clinic specialist will always help you choose the crown material and the correct size.

Grillz for teeth (Grillz, Grillz for teeth)

Grillz are , coupled with Trap or Rap music and the SWAG style. Now the opportunity to make professional grills has appeared in St. Petersburg , at the Medent dental clinic. We are the only clinic in St. Petersburg that has created a professional direction for the production of dental jewelry - grills, skyes, fangs.

Grills are individually made overlays for teeth that are absolutely safe for enamel, as they are covered on the reverse side with a special bio-compatible protective coating. Grills are decorative metal overlays for teeth that are installed on top of your teeth and can be independently removed and reinstalled at any time. To make them, an exact impression of your teeth is taken and then a personal grill is made for you, which you can put on and take off yourself at any time. Grills can be installed either on several teeth, or completely on the upper or lower jaw, or on all teeth. It is fashionable to put grillz on only one jaw in combination with snow-white teeth on the second jaw. At Medent Dentistry, you can painlessly and safely for your enamel have professional teeth whitening to a bright snow-white color and make grills of any modification - silver, gold, any other color, with stones, patterns - whatever. We professionally manufacture grills using proprietary titanium alloy and fully bio-compatible materials from coating to protective layer. We have mastered the production of grills to perfection and are ready to offer you the creation of grills of any complexity. How does grillz stay on your teeth? Professionally made grillz adhere to the teeth due to a special protective coating inside the grillz, which is lightly suctioned to the teeth and at the same time protects the metal part of the grillz from coming into contact with the teeth, as well as due to the precise repeatability of the contour of your teeth by the grillz.

Grillz made from titanium alloy are the safest material for making real individual grillz. These grills completely follow the contours of your teeth and are secured using a special insert integrated into the inside of the grill, which 100% protects your teeth from contact between teeth and metal. This type of grill is completely safe for your teeth. Grillz made from titanium alloy do not oxidize at all, thereby maintaining fresh breath and a feeling of cleanliness while wearing the grillz. At the initial appointment, you will discuss in detail with the specialist the length of the grill being produced (for how many teeth), its shape, color, inscriptions, cutouts on the grill, engraving, notches or diamond cut. It is highly advisable that you come with a photo of the grillz you like. The process of buying a grillz 1) You make an appointment, for example by calling: (812) 777-234-8 or +7 (911) 923-05-25 2) At the appointment you discuss with a specialist your wishes and all the intricacies of making your grillz, after which a special impression is taken of your teeth, according to which a grill that exactly follows the contours of your teeth will be made. 3) Making a grill usually takes about a week. As soon as your grillz is ready, our specialist will contact you so that you can try on and pick up your finished grillz.

Thanks to the Medent dental clinic, it is now possible

to buy grills in St. Petersburg Cost of grills 1) Taking an impression + correction + making a model = 1,500 rubles 2) Making a simple silver grill from titanium alloy (without drawings or engravings) = 3,300 rubles 3) Gold plating on grills = 5,000 rubles

Sign up for a free consultation with a dentist

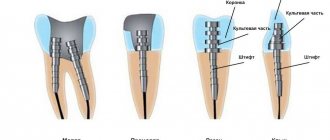

Crown manufacturing sequence

The stages of installation of stamped crowns can be divided into laboratory and clinical. The first involves the work of a dental technician in a laboratory. The second involves performing procedures in the dentist’s chair.

In addition, in the process of manufacturing these orthopedic structures, various devices are used, and there are also special features when installing the product.

Manufacturing rules

The production of sleeves occurs by drawing sheet material on special machines. They are different. The mold of some models is presented in the form of two disks. One of them has two punches. This term means "cylindrical rod". And on the second there are holes of the corresponding diameter. Manual devices. They work through the interaction of a lever and a screw. Pneumatically driven device.

The broaching process itself is divided into stages. The sleeve is drawn out gradually. As a result of the first stage, when the press is connected to the punches, the sleeve takes the shape of a cup. At first, its dimensions do not quite correspond to the required ones, but, passing through all the matrices, it is brought to the standard size required for the application. If you skip at least one step in order to speed up production, you can reject the part.

The process of manufacturing and installing orthopedic structures

The manufacture of a stamped crown requires compliance with the following algorithm of actions:

- Initially, an examination of the oral cavity is performed. If there are carious lesions on the tooth surface, they are completely sanitized with the installation of fillings.

- Grinding tooth enamel involves removing it to the thickness of the structure being installed.

- The patient decides on the choice of color. Products can be coated (like a precious metal), or installed without it.

- Taking impressions of the prosthetic jaw. An auxiliary impression is taken from another jaw row to ensure proper fixation of the plaster model.

- The production of a plaster model based on the impression is carried out by a dental technician in a laboratory setting. Subsequently, the resulting models are fixed in an occluder, which allows for correct comparison of the incisors and molars of the upper and lower rows.

- Wax is applied to the plaster model , after which the structures are closed for ease of restoration of the chewing surface.

- Initially, dies are made from gypsum , after which they switch to using metal alloys.

- The final stamping stage takes place taking into account giving the model the required shape and diameter. After this, the structure is transferred to the dentist.

If the fitting is not accompanied by the appearance of unpleasant sensations, and the structure is tightly located on the prosthetic tooth, then it is fixed using a special cementing composition.

You should be aware that metal products have a limited service life. The maximum is 5 years. But most practitioners advise renewing the crown of the tooth after 2 or 3 years.

This is due to the need to assess the condition of the dentin, since its destruction may occur under the structure.

Devices

In order for the sleeve to take on an orthopedic shape, 2 devices are used. Their design works on the principle of a hand press.

Devices for stamping metal crowns.

| Serial number | Apparatus | Short description |

| 1 | Samson's design | The design of the apparatus allows for stepwise drawing of cartridges using metal blanks. It is based on a cast iron bed, which is equipped with two dies (top and bottom) with 15 holes in each. The slider moves along the frame guides. During movement, the punches penetrate the holes of the die, which ensures the molding of the sleeve. Gradually moving the resulting cup into the next holes allows you to give the product the desired diameter. |

| 2 | Sharp apparatus | Used for pulling metal workpieces. It consists of two disks placed on a stable frame with a screw and a handle. On the surface of the upper disk there are punches, which coincide in number with the holes on the lower one. By turning the screw handle, the punches pull the metal structure through the holes on the lower disk. |

This is interesting: When is the installation of a composite bridge justified?

The video shows the process of making a stamped crown.

Cobalt-chrome casing: the history of Grillz Minsk

A dental accessory from America in the 80s has migrated to Belarus: a team creating custom grills has appeared in Minsk. We met with the Grillz Minsk duo and found out what grillz are made of, how much a “golden” smile will cost and why metal on teeth is cool.

Kostya

Anton

30 years ago, American dentist Eddie Plain decorated the teeth of rapper Just Ice with gold plates - thus the first grillz were born, launching the trend for a metallic smile. Until the 2000s, this accessory was perceived exclusively as an attribute of hip-hop, but in the 21st century, grillz got out of the mouths of rappers in the American south and found themselves on the teeth of pop artists, actors, etc. Now grillz are experiencing another heyday: rap freshmen boast about them, they are sold at auction and made in Minsk. Anton and Kostya are responsible for the last point - a compact team that decided to bring a little dental exoticism to Belarus.

In fact, grillz are a cast tooth: grandmothers used to have such teeth made of gold, and grillz are made using the same technique, only they are attached to “living” teeth. The guys started with simple “pieces of iron” attached to the teeth, and then, having gained knowledge about manufacturing methods and materials science, they began to pour silicone into the grills.

Kostya: I’m from Minsk, but for some time I lived in St. Petersburg. There I saw this culture with grillz - before that I had seen them in videos, but in real life they look especially interesting. When I returned to Minsk, I realized that no one was doing this here, so Anton and I thought that we could fit into this unoccupied niche.

Previously, Kostya did covers of Eminem, and then he went solo, and he met Anton, his partner, just after his solo concert.

“You can’t make grills out of stainless steel, because it might get corroded because of some cola.”

Anton: After the concert, we hung out at his house, and Kostya said that he had a problem with his teeth. And I’m a dental technician by profession, so I answered him something like: “Okay, no market, I’ll help you, I won’t even take money - just take me to your skating rink, I want to hang out with you.” That's how it all started.

Then I worked as a dental technician in a company, and the boss there asked me to make grills for some grandson. I made them, took pictures, showed them to Kostya, and everything developed into the grillz that we make today.

We make grills from cobalt-chrome alloy - this is an alloy used in dentistry for crowns and other things. I also put silicone in the grills - it is needed so as not to damage the enamel.

We use a dental alloy of metals because the grills are attached to the oral cavity, and there are a lot of things there - you can’t make grills from stainless steel, because it can become corroded due to some cola. This will not happen with this alloy - this is the metal that is not scary to shove into your mouth.

– What colors do you make grills in?

Anton: There is silver, “Indian” gold and zirconium gold. We don’t have the jaundiced color that guys in the West wear—we have a different taste.

If you have silver grills, you can walk around with them and repaint them in the future - you give me the grills, and I will repaint them gold. You walk around with gold and then you say, man, I want my silver back - no problem, I'll make them silver again. This is not a problem because it is just a spray.

– Is it possible to paint the grills a brighter color, for example purple?

Anton: The problem is that I both pour and spray grills in dental areas. And they don’t do violet spraying there - they only have what’s used in dentistry. In theory there is titanium that can be made in a shade of purple or green, but I haven't found a place that can get me titanium alloy grills.

At the dental clinic, guys are pouring out a mold. They take impressions of their teeth at home - Kostya usually does this. Afterwards, Anton takes the casts and works on them in the dentistry - from there he brings ready-made grills, into which, after subsequent fitting, silicone is poured, which completely follows the shape of the client’s teeth.

On average, they make grills in 14 working days, but the deadlines may change - if the client wants grills for two jaws with ten teeth each, then Anton will “grind” them a little more. At the same time, one tooth can be done in a couple of days, but on average everything revolves around two weeks.

“Alika grills are made with the help of two Chinese - one makes it and the other delivers, and five people are involved in working on our grills.”

– Which grills are the most popular?

Anton: Most often they take grillz for two teeth and put them on the fangs. But we advise you to fasten two on each side - this is not to rip off any money from you, but in terms of reliability of fastening: this will be more practical, because silicone wears out faster on single teeth. The more teeth you make, the longer and better the silicone sits.

In general, boys like to lusciously “sandalize” half their jaws, and grillz for one or two teeth are popular among girls. Although there was a client who made three grills for herself.

– Why do grillz have such a “biting price”?

Anton: There are people who come to our group and say: “Damn, 40 rubles per tooth, what the hell, why is it so expensive? I’ll go to Alik and buy grills there.” And there are grills there, and you should have seen these “squares” - models for the entire jaw there cost one dollar. But these grills are like the vampire jaws that used to be sold in stalls - you close your mouth in them, and your lip sticks out. This is complete crap, and our grills are completely handmade: one person’s model simply won’t suit another. I model the shape by hand and in principle I can do almost anything - it all depends on time.

I do everything by hand, and it’s not that easy because it’s labor-intensive work. And some stages cannot be done by myself - in the laboratory I can model, saw and polish, but I need to give the model on which the grills themselves will be modeled to the foundry and pay the people who will do this. Then you pick it up, model it and take it to the people who will pour the metal - again you need to pay the person who will pour it. It turns out that Alika grills are made with the help of two Chinese - one makes it and the other delivers, and five people are involved in working on our grills. Due to this, the price is such that the material is also included.

Kostya: If Moscow manufacturers see the prices for our grills, they will simply kill us: “Why is it so cheap?” Everything they have is 2-3 times more expensive, and I made grills for six teeth in Moscow for 20 thousand Russian rubles (about 640 BYN) - here such a set will cost a hundred dollars.

We are currently developing grills with different stones. Essentially, these are like varieties of sneakers: if you start making sneakers, then you need to do something with both thin and thick soles. And grills with stones are needed so that people can choose. We need to reach a level where we can fulfill any order.

We are also thinking of making grills from plastic: using the same technique, with silicone, but in different colors - schoolchildren often write to us who want the same teeth as 6ix9ine. And the cost of such grills will be less.

– Will you make grills for a schoolboy? The same tattoos in salons are done only from the age of 18.

Anton: Let's do it. We didn’t worry about the fact that someone’s dad would come and clean up my face because I stole his child’s money and teeth and did some incomprehensible crap. In general, my dad would rather clean up a tattooist’s face than mine—a tattoo is more difficult to remove than grillz.

– Do you need to take off your grillz or can you wear them all the time?

Kostya: These things are not intended for everyday use: if I want to eat or talk without distortion, then I will take them off and move on with my life. I take my grillz to some shoots and parties.

Anton: You need to understand that grills are an accessory. These are not crowns that are made so that you can live a normal life - they are just decoration with which you will look beautiful in the photo and stand out in the company. When we talk about caring for grills, we say that you need to wear them when you go to some kind of party, but you don’t need to eat or sleep in them. In general, sleeping in grillz is the last thing, because in a dream “single” grillz can be easily swallowed - it’s okay if they just “pass” through you, but they can also get caught somewhere inside with a fastener, and this will not fun. Therefore, protect yourself, do not do unnecessary things.

“If Moscow manufacturers see the prices for our grills, they will simply kill us: “Why so cheap?”

Now the guys are taking impressions of the house, while simultaneously creating their own studio: Kostya and Anton want to make a presentable place. The guys want to reach a professional level, so now they earn and save so that their clients come to a beautiful room with good equipment.

– What is your “flow” of clients?

Kostya: On average we have one order per week. It doesn’t happen every once in a while: it happens that three people come in a week, but some are postponed, others don’t come at all. It happened that we did nothing for several weeks, and then a bunch of people flew in to visit us.

– Is it possible to earn some income from grills?

Anton: So specific that you won’t work anywhere else – no. Most often we work for zero: earned - invested, earned - invested. I think this is a classic start for every business, but we manage to save money to build a studio.

– Why are grillz cool?

Kostya: Grillz are a great way to freshen up an image, and you can do different things with them. We are for people to stand out and do something interesting for themselves - we do not suggest that people fill their teeth and walk in line, but push them towards some kind of uniqueness.

Anton: We are so accustomed to a certain “sameness” that when I ride on the bus in sneakers of different colors, other passengers look at me like I’m a fool. Grillz are a way to break out of this “normality”, from invented norms. So be individual and don't be like everyone else.

Photo: Tanya Kapitonova

11025

Do they cause harm?

Most of all, patients are concerned about the issue of safety - is it worth exposing their teeth to such an influence, will this end in dental problems?

Since it is an artificial structure, unnatural for the oral cavity, it can cause various reactions in soft and hard tissues. But the problem lies not so much in the products themselves, but in their quality, materials used, methods of fastening and hygienic dental care.

Dentists urge you to pay the greatest attention to the quality of the selected product before installation - it must be made of biocompatible materials and without sharp corners. This is the only way to prevent unpleasant consequences.

If the product was purchased without such precautions, then there are frequent cases of adverse reactions:

- allergy to the composition of the alloy used to create them;

- inflammatory processes of the gums due to mechanical damage or insufficient cleaning of contaminated surfaces;

- risks of carious cavities;

- injuries to the tongue, lips, gums, and the inside of the cheeks, which is associated with uneven edges or the presence of stones in the product;

- irritation of the mucous membrane from contact with an artificial structure;

- malocclusion from frequent wearing of bulky products.

If you experience any unpleasant sensations or discomfort, you should immediately visit the dentist.

Where to buy and how much do they cost?

Stamped products are sold in online stores. But in order not to harm your dental health, you should carefully check the availability of certificates for these jewelry. You also need to understand that they cannot be cheap. If the price of cartridges is within 3 dollars, then this indicates low quality and the dubious composition of the alloys from which they are made.

The most desirable and reliable are individual designs created to order in special clinics. To do this, you should find a dentistry in your city that has a high reputation, and the doctors working in it are considered qualified specialists. They will not only make a safe and perfectly shaped plate, but will also advise on selection and operation.

The cost varies greatly depending on their shape, size, how they are made and where you purchase the structure. Simple stamped models made of chrome and nickel or silver can cost between 200-600 rubles.

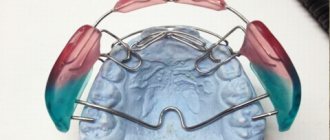

What are grills?

Although multi-colored stones were inserted into teeth back in the Mayan tribe, dental jewelry such as grillz appeared in the 80s. They were made by dentist Eddie Plain for one of the rappers, after which this accessory became firmly established in the culture of hip-hop artists. While most mortals are discussing how to achieve an even, white-toothed smile, choosing what to install, veneers or braces, the fashion for golden, rough and scary-looking crowns has returned in rap culture.

Grillza on teeth became especially fashionable with the release of the video of the same name by rapper Nelly in 2005. Since then, gold teeth grills, the price of which sometimes exceeds the cost of a villa on the seashore, have also been worn by female celebrities: Rihanna, Beyonce, Kim Kardashian and even Madonna.

In essence, the accessory is an overlay on a tooth, several teeth, or the entire jaw at once of an unnatural color and shape . The most popular flowers are:

- gold grills;

- silver grills;

- white;

- multi-colored;

- inlaid with rhinestones or precious stones.

In shape, it can be an imitation of natural teeth, arches, squares, pointed “vampire” fangs and other fruits of fantasy. As a rule, girls prefer jewelry for 1-2 teeth, and guys prefer jewelry for the entire dentition and both jaws.